The Ultimate Guide to Label Roller Machines: Enhancing Your Packaging Efficiency

In today's fast-paced business environment, every company is constantly searching for ways to improve their operational efficiency and reduce costs. One of the most effective ways to achieve this, especially in the packaging industry, is through the use of advanced machinery such as the label roller machine. This article will explore this essential equipment, breaking down its functionality, benefits, and the various critical factors that make it a vital asset for businesses involved in packaging.

What is a Label Roller Machine?

A label roller machine is a specialized piece of equipment designed to apply labels onto a variety of products and packaging materials efficiently and accurately. These machines are used across numerous industries, including food and beverage, cosmetics, pharmaceuticals, and logistics, to streamline the labeling process.

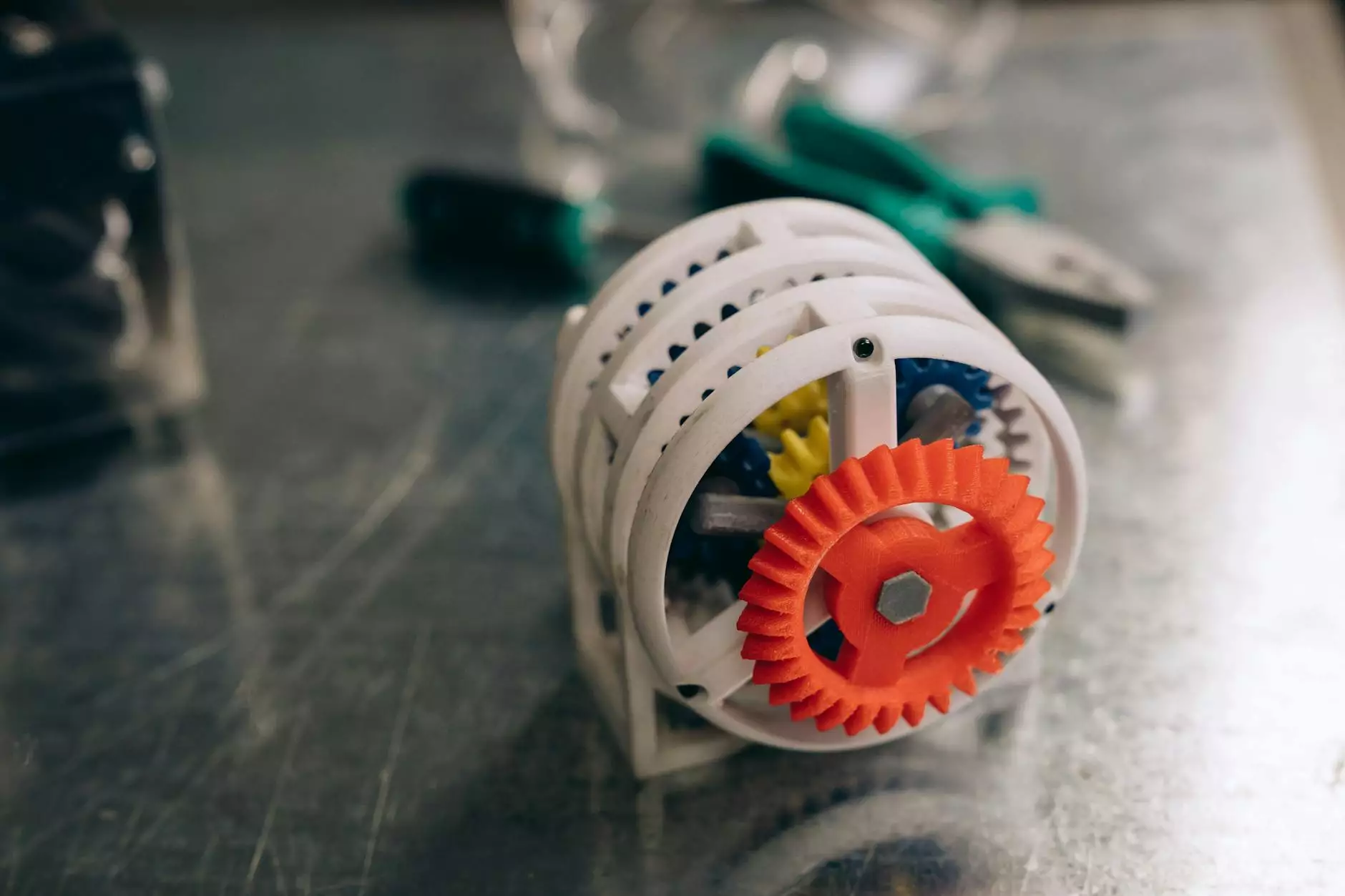

The Components of a Label Roller Machine

To understand how a label roller machine works, it’s essential to recognize its basic components:

- Label Roll Holder: This holds the roll of labels that will be applied to the products. It typically accommodates various label sizes and materials.

- Dispensing Mechanism: This is responsible for unwinding the label from the roll and presenting it to the application surface.

- Application System: The most crucial part, this system uses different methods (pressure-sensitive, heat transfer, etc.) to adhere the label to the product.

- Control Panel: This allows the operator to set parameters such as label speed, position, and alignment.

Why Your Business Needs a Label Roller Machine

Investing in a label roller machine offers a plethora of advantages for businesses looking to enhance their packaging processes. Some notable benefits include:

1. Increased Efficiency

Manual labeling is not only time-consuming but also prone to errors. A label roller machine automates the labeling process, significantly speeding up operations letting you focus on other critical areas of your business.

2. Consistency and Accuracy

Maintaining consistency in labeling can be challenging when done by hand. Machines ensure that each label is applied accurately and uniformly, maintaining high quality and brand integrity.

3. Cost-Effectiveness

While the initial investment in machinery might seem significant, the long-term savings in labor costs and increased productivity can lead to higher profit margins.

4. Versatility

Label roller machines can handle a wide range of products and label types. Whether you are dealing with glass bottles, boxes, or bags, a suitable machine can adapt to your specific needs.

5. Improved Safety

By automating the labeling process, you can reduce the risk of workplace injuries associated with repetitive manual tasks, thus enhancing employee safety and morale.

Different Types of Label Roller Machines

The diversity in packaging needs has led to the development of various types of label roller machines. Here are some commonly used types:

1. Manual Label Roller Machine

This entry-level option is perfect for small businesses that do not have a high volume of products to label. It requires human operation but provides a cost-effective solution.

2. Semi-Automatic Label Roller Machine

Semi-automatic machines require some manual input but can significantly speed up the process compared to manual labeling. They are ideal for medium-sized operations.

3. Fully Automatic Label Roller Machine

For large businesses with high production rates, fully automatic machines are a must. They require minimal human intervention and can handle high throughput while maintaining accuracy.

4. Specialized Label Machines

Some businesses may require custom solutions for specific labeling challenges, such as applying labels to irregular or complex shapes. Specialized machines can provide tailored solutions for these unique needs.

How to Choose the Right Label Roller Machine for Your Business

Choosing the right label roller machine can be an overwhelming task. Here are some critical factors to consider:

1. Production Volume

Evaluate your business's labeling needs. If you have a high production volume, investing in a fully automatic machine will yield better results. Conversely, low-volume operations can benefit from manual or semi-automatic machines.

2. Label Size and Type

Be mindful of the size and type of labels you need to apply. Some machines are versatile and can handle various sizes and materials, while others are specialized.

3. Integration with Existing Systems

Ensure the machine can integrate with your current production line. Compatibility with other packaging equipment and your warehouse management system may improve overall efficiency.

4. Budget

Consider both the initial purchase cost and long-term operational expenses. Higher-priced machines may provide better reliability and lower maintenance costs, but ensure it fits within your budget.

5. Manufacturer Reputation

Always choose a reputable manufacturer like Shineben. Quality machines and reliable customer support can significantly enhance your investment.

Maintenance and Care for Your Label Roller Machine

Regular maintenance will ensure that your label roller machine operates efficiently and lasts for years. Here are essential maintenance tips:

- Regular Cleaning: Dust and debris can affect machine performance. Clean the machine regularly according to the manufacturer’s guidelines.

- Check for Wear and Tear: Inspect essential parts regularly for signs of wear and replace them as needed to prevent breakdowns.

- Keep Software Updated: If your machine has software components, ensure they are regularly updated to enhance performance and security.

- Service by Professionals: Schedule routine professional servicing to address any potential issues before they become serious problems.

Conclusion: Elevate Your Business with Shineben's Label Roller Machines

By understanding the importance and functionalities of a label roller machine, businesses can vastly improve their packaging efficiency. Whether you are a small startup or a large enterprise, investing in high-quality labeling equipment from a reputable manufacturer like Shineben can make a significant difference in your labeling processes. With benefits ranging from increased operational efficiency to enhanced safety, the return on investment is clear.

For any business looking to stay competitive, a label roller machine is not just an option; it is a necessity. Explore your options today and take your packaging solutions to the next level!