The Ultimate Guide to Business Success with Wood Briquettes Manufacturers

The global demand for sustainable, eco-friendly energy sources has surged dramatically over recent years, driven by increasing environmental awareness and rising costs of traditional fossil fuels. Among the innovative solutions leading this green revolution are wood briquettes. These compressed biomass units serve as an efficient, renewable, and cost-effective alternative to conventional firewood and fossil fuels. Central to this industry are wood briquettes manufacturers, whose expertise and innovative manufacturing techniques are shaping the future of sustainable energy and firewood markets.

Understanding the Role of Wood Briquettes Manufacturers in the Energy Market

In the expanding landscape of renewable energy, wood briquettes manufacturers play a pivotal role by transforming raw biomass material into high-density, easy-to-handle fuel sources. Their operations encompass sophisticated processes like biomass compression, binder application, and quality control, ensuring their products meet global standards and consumer expectations. These manufacturers are instrumental in promoting a cleaner, greener environment while also providing economic opportunities within the firewood and biomass sectors.

Why Wood Briquettes Are Revolutionizing the Firewood Industry

The traditional firewood industry faces numerous challenges, including energy inefficiency, inconsistent quality, and environmental concerns. Wood briquettes manufacturers address these issues by producing uniform, energy-efficient, and environmentally friendly briquettes. These benefits include:

- High Energy Density: Briquettes burn longer and provide more heat compared to traditional firewood, making them cost-effective for consumers and businesses alike.

- Clean Combustion: Reduced smoke and ash emissions contribute to healthier indoor and outdoor environments.

- Ease of Handling and Storage: Compact and uniform form factor simplifies transportation and storage logistics.

- Renewable and Sustainable: Made from recycled wood or biomass waste, supporting environmental conservation efforts.

- Cost Efficiency: Lower transportation costs due to their density and ease of handling increase profitability for manufacturers and distributors.

The Manufacturing Process of Wood Briquettes: A Deep Dive

To understand the significance of wood briquettes manufacturers, it’s essential to explore their production processes, which combine technology, sustainability, and quality control:

Raw Material Selection and Preparation

Manufacturers typically source biomass from wood waste, sawdust, shavings, and other forestry residues. These raw materials are processed to achieve optimal moisture content, usually below 15%, which is critical for producing high-quality briquettes.

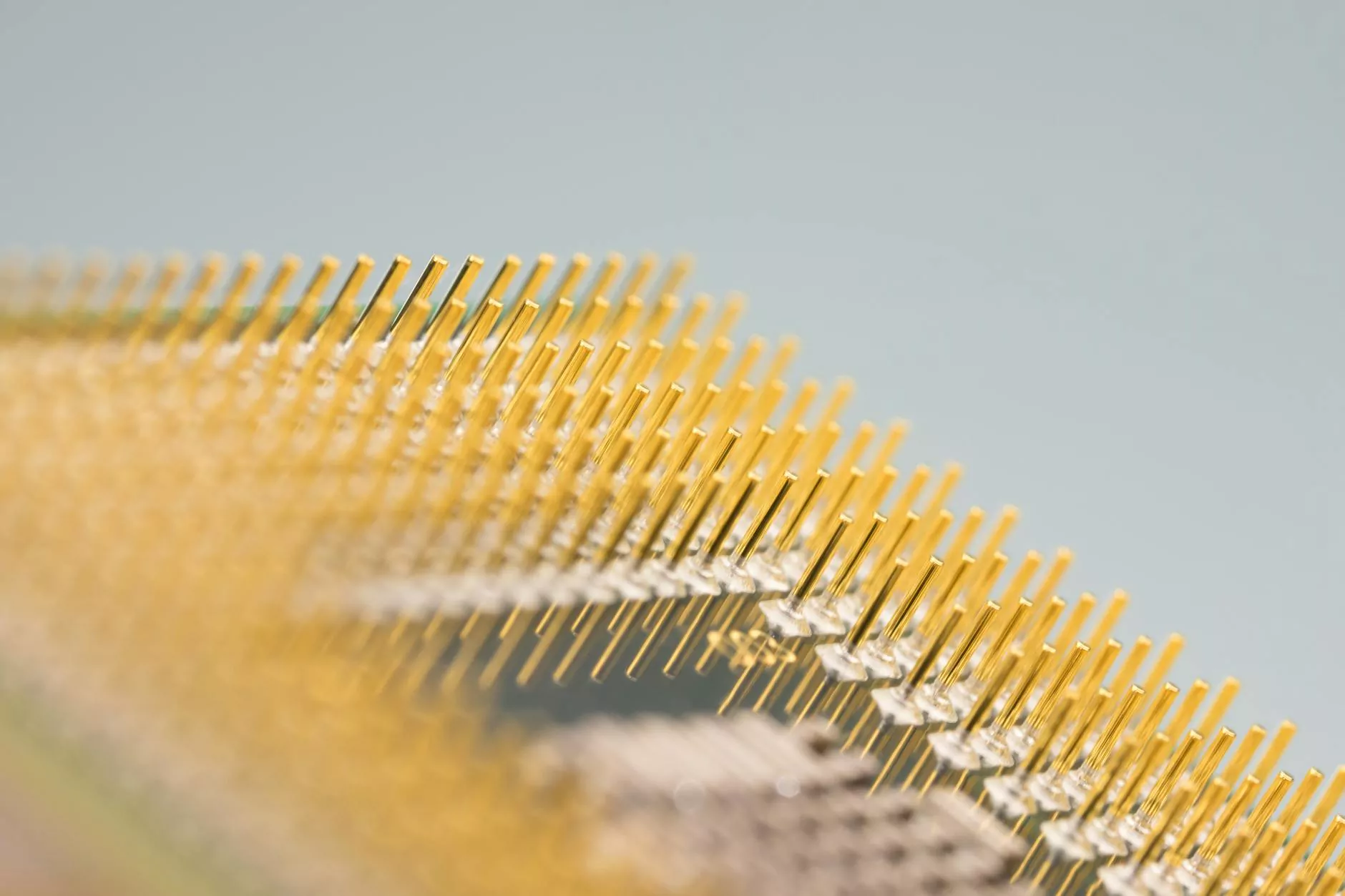

Compression and Binding

Using hydraulic or mechanical presses, the raw biomass is compressed under high pressure to expel moisture and air. In some cases, natural binders like lignin are utilized, which melt during compression, acting as a natural glue, ensuring the briquette’s strength and durability.

Cooling and Packaging

Once formed, briquettes are cooled to stabilize their shape and moisture content. They are then sorted, quality-checked, and packaged for distribution, ensuring that customers receive premium products that meet industrial and consumer standards.

Key Factors Contributing to the Success of Wood Briquettes Manufacturers

Success in this industry hinges on several critical factors that talented wood briquettes manufacturers master:

- Advanced Technology: Investing in modern machinery to increase efficiency, reduce waste, and enhance product quality.

- Sustainable Sourcing: Ensuring raw materials are obtained responsibly, supporting eco-friendly practices and certification standards.

- Innovative Product Development: Creating diverse briquette sizes and types to meet varied market demands, from household consumers to industrial clients.

- Quality Assurance: Implementing rigorous testing protocols to ensure consistent burn characteristics, low emissions, and durability.

- Market Expansion and Branding: Building strong relationships with distributors and retailers while promoting the environmental benefits of briquettes.

Market Trends and Future Outlook for Wood Briquettes Manufacturers

The industry landscape is continuously evolving, driven by regulatory changes, technological innovation, and consumer preferences. Here are some prominent trends shaping the future of wood briquettes manufacturers:

Rising Global Demand for Renewable Energy

With governments worldwide implementing stringent environmental policies, the demand for renewable alternatives like briquettes is expected to grow exponentially. Countries aiming to reduce carbon emissions are incentivizing biomass energy investments, opening vast opportunities for manufacturers.

Technical Innovations in Production Processes

Emerging technologies, such as automated pressing machines and moisture control systems, significantly enhance production efficiency and product quality. Additionally, the integration of IoT (Internet of Things) enables real-time monitoring and optimization of manufacturing lines.

Expansion into New Markets

Emerging economies with expanding energy needs are becoming attractive markets for durable, reliable biomass fuels. Expanding infrastructure and increasing environmental consciousness foster opportunities for manufacturers to penetrate these regions.

Sustainable Practices and Certification Standards

ISO certifications and sustainable forestry certifications (like FSC) are gaining prominence. Manufacturers adhering to these standards will enjoy greater trust and access to environmentally conscious markets.

Business Opportunities for Aspiring Entrepreneurs and Investors

Entering the wood briquettes manufacturing industry presents numerous lucrative opportunities:

- Establishing a Production Plant: Scaling operations starts with strategic site selection, raw material sourcing, and technological investment.

- Creating a Distribution Network: Partnering with firewood suppliers, energy providers, and retail outlets enhances market reach.

- Innovating Product Lines: Developing specialized briquettes (e.g., flavored, extra-long burning) can attract niche markets.

- Implementing Sustainable Practices: Ensuring eco-friendly sourcing and manufacturing boosts brand reputation and regulatory compliance.

- Engaging in Export: With growing global demand, export opportunities to Europe, North America, and Asia are promising.

How wood-trans.com Supports Wood Briquettes Manufacturers

As an industry leader, wood-trans.com offers comprehensive solutions tailored to wood briquettes manufacturers. From machinery supply, raw material logistics, to technical consultancy, their expertise enables manufacturers to optimize their production processes and achieve sustainable growth. Their focus on quality, reliability, and innovation makes them a trusted partner in transforming biomass into superior briquette fuels.

Concluding Remarks: Building a Sustainable and Profitable Business

In the rapidly expanding world of renewable energy, wood briquettes manufacturers are at the forefront of a green revolution. Their ability to produce high-quality, eco-friendly fuel sources aligns with global efforts to combat climate change and promote sustainable development. Success in this industry relies on technological advancement, responsible sourcing, and strategic market expansion. Industries and entrepreneurs who embrace these principles will not only contribute to a healthier planet but will also unlock profitable business opportunities in a future where renewable energy sources dominate.

Seizing the opportunity within this sector demands innovation, dedication, and a clear understanding of evolving market dynamics. As the industry grows, so do the possibilities for sustainable enterprise, making it an exciting, impactful, and lucrative pursuit for committed wood briquettes manufacturers.